COMPACT-ALPHA

Engineered for Automotive Testing

Advanced Automotive Inspection Stations use AI-guided vision systems to detect cracks, surface damage, and defects across engine splash shields, dashboards, and chassis. Powered by COMPACT-ALPHA with PWM control, the lighting provides flawless visibility for every angle — a precise flashing sequence, photometrical tuning to ensure safety compliance.

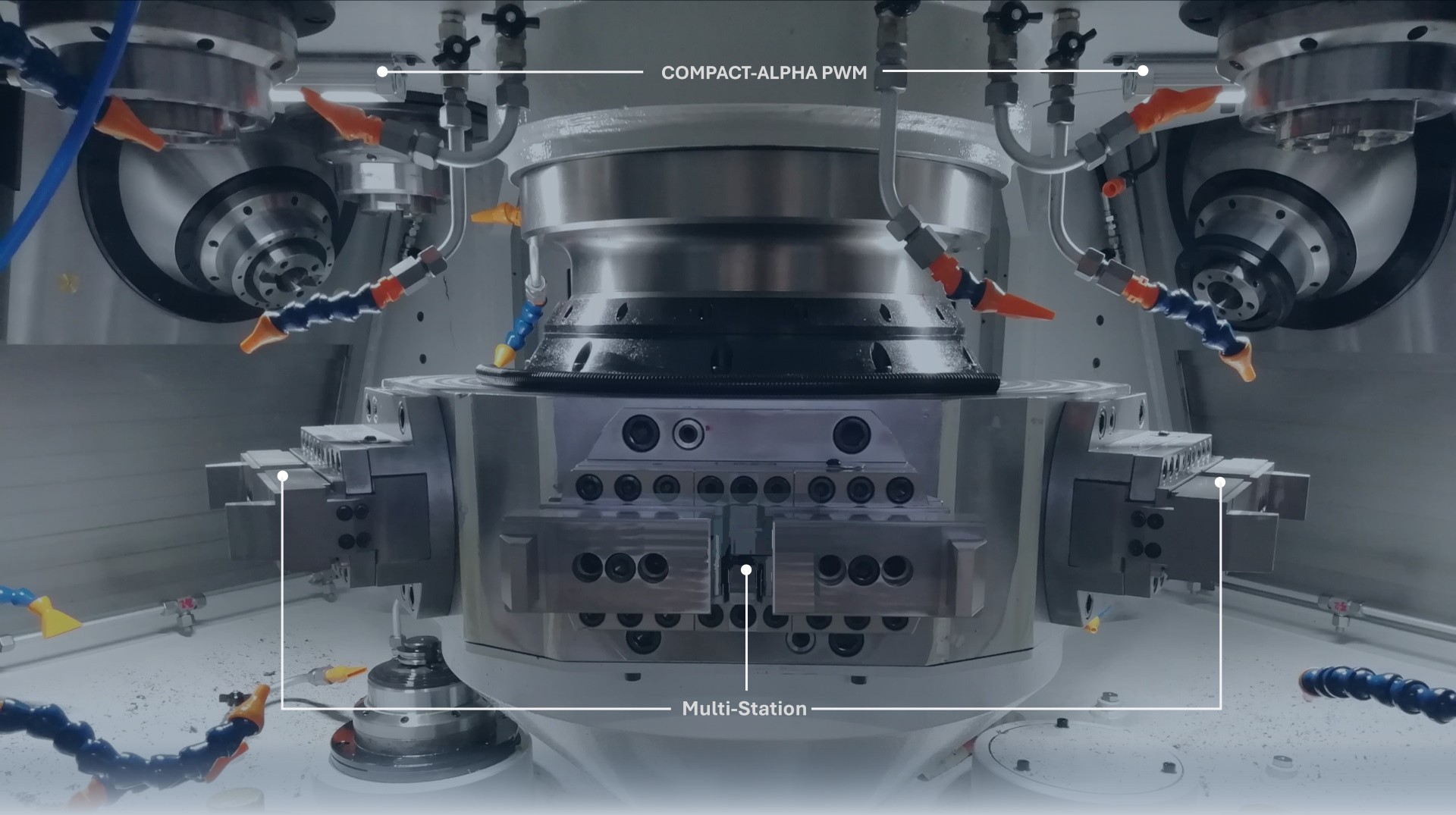

Developed for CNC application

Modern CNC machines execute precise programmable movements for machining metal, plastic, and composite components. These operations involve high-speed cutting tools, tight tolerances, and real-time observation of tool paths, surface finishes, and chip formation. COMPACT-ALPHA offers precise, adjustable lighting that enhances visibility during machining operations. PWM technology-dimming provides an effective way to control the brightness of LEDs, minimizing noticeable flickering, improving energy efficiency, and ensuring consistent color quality.

Features

Powerful brightness – 3 optics

30°, 90°, 110° Beam Aperture

- condense, Narrow, wide

- Lighting uniformity

- Up to 108 lm/W

- 5000 K – CRI 85

- RG1 Photobiological Risk – IEC 62471-5:2015 © IEC 2015-

Built for Resistance

- Impenetrable enclosure

- 24 Vdc built-in Drivers,

- 10-foot cord or M12 connector Electrical service

- PWM Interface

- IP67 – IP69 reliable for Micro-Blasting, Transfer CNC, Grinding Machines, Induction Brazing CNC

- PWM Interface

- Reparable in 10 years of work in harsh application

Mounting

CAFX02 – Kit-Stainless steel Brackets

- It is a 70° angle adjustment bracket that is robust, versatile, and vibration-resistant. Made of stainless steel, it is the perfect solution when you need to adjust the direction of the flow beam even in high-vibrating applications.